Spray drying is the transformation of feed from a fluid state into a dried form by spraying the feed into a hot drying medium. The process is a one step continuous operation. The feed can be either a solution, suspension or a paste. The spray dried product conforms to powder consisting of single particles or agglomerates, depending upon the physical and chemical properties of the feed and the dryer design and operation. During the last three decades spray drying has undergone an intensive research and development, so that modern spray drying equipment can meet the requirements to produce a powder with tailor-made specifications required by the end-user.

For a given dryer capacity, the properties of the liquid to be dried,

For a given dryer capacity, the properties of the liquid to be dried,

the particle size distribution, and the quality of the powder to be produced

are most important, and these must be carefully considered when selecting the design of spray dryer and the type of atomizer.

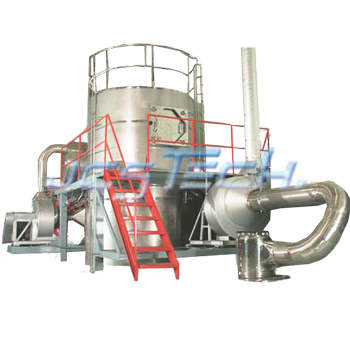

The Design following main components;

- Drying chamber

- Hot air system and air distribution

- Feed system

- Atomizing device

- Powder separation system

- Pneumatic conveying and cooling system

- Fluid base after-Drying/cooling

- Instrumentation and automation

Model : SPD-NZ1000

Capacity : 1000 L/hr

Our The spray dryer can be equipped with either a rotary atomizer, Pressure nozzle or a two-fluid nozzle and is recommended for those products classified as ‘easy-to-dry

Model : SPD-AT10

Capacity : 10L/hr

Model : SPD-NZ50

Capacity : 50L/hr

Model : SPD-NZ100

Capacity : 100L/hr

Double-stage-Spray dry

For specialty products that require good solubility by adding options such as fluidized-base for agglomerate. The fluid machines use turbulent air as the working powder depending upon the purpose.

In addition,Most powdered products are relatively high cost. Losses during the process are important. We have an additional design in the Encapsulated ,Bag-filter and Flavor-catcher system.

Experience More...

Ice-cream Batch Freezer

Spray dry Complete line

Pasteurizer Homogenizer and Others.

A quality Machinary will make well.. Products.